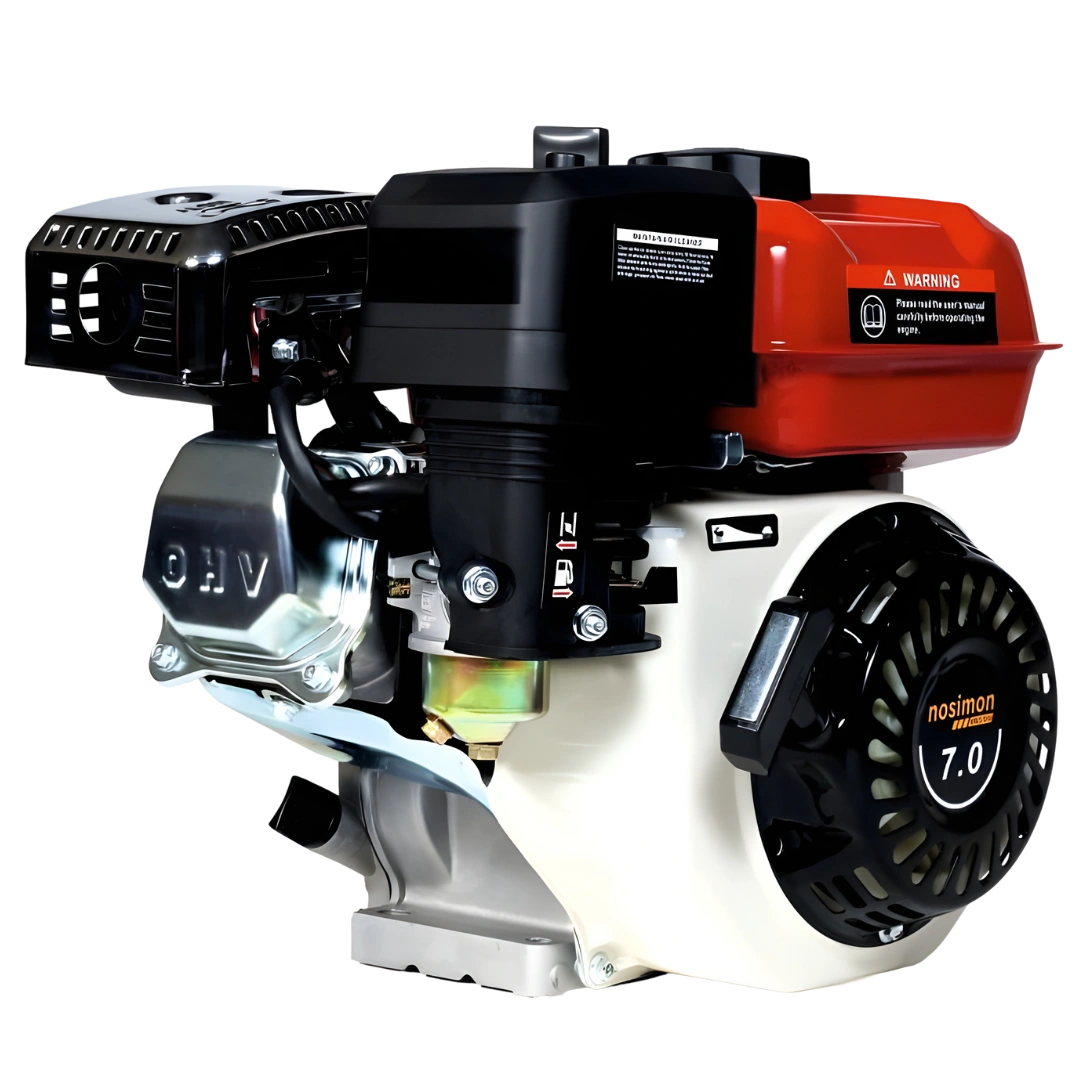

Built to Power Indian Agriculture

Experience robust 212CC 4-stroke engines delivering 3.9 kW power at 3600 RPM. Designed for agricultural machinery and field operations—these engines ensure consistent performance, long service life, and dependable output across varied working conditions.

Designed to deliver real value by mechanizing key tasks and boosting productivity

Farmer From

This brush cutter from Royal Kissan Agro is strong and easy to operate. It cleared thick weeds in my field quickly, making farm work much easier

Farmer From

Royal Kissan Agro’s water pump in Tamil Nadu delivers water strongly and reliably. It keeps our irrigation running even in dry spells and has boosted our rice yield

Farmer From

In Telangana I rely on this chaff cutter for my cattle fodder. It shreds stalks finely and quickly, saving hours of work and helping my cows eat better

Farmer From

The chainsaw from Royal Kissan Agro is strong and easy to handle. In Andhra we use it to cut firewood and clear branches; it works quickly with no issues

Farmer From

Royal Kissan Agro’s hose pipe is flexible and durable. In Karnataka, it's essential for irrigating my tea plantation, delivering water evenly without any leaks

Farmer From

This sprayer from Royal Kissan Agro sprays evenly and is easy to carry. In Kerala’s paddy fields, it helped me apply fertilizer quickly and improved my harvest

Everything you need to know about our products and services

Yes. They are designed with rugged construction—high-grade steels, reinforced frames and heavy-duty wear parts—so they withstand repeated strain, thick vegetation and uneven terrain without premature failure.

Yes. Designs prioritise ergonomic controls, intuitive linkage/attachment points and straightforward control layouts to enable rapid hookup and efficient operation by experienced operators.

Routine tasks include removing crop residue and dirt, lubricating moving parts, checking and replacing filters, inspecting belts and hoses, topping fluids, and tightening fasteners. Components are positioned for straightforward access to reduce service time.

Follow a usage-based schedule: routine inspections every 50–100 operating hours, with more comprehensive servicing at season end. Also perform quick pre-use checks (fluids, guards, driveline) before extended jobs.

No specialised certification is generally required; operators with solid mechanical experience and familiarity with farm implements can operate and maintain them safely after reading the manual and receiving basic familiarisation.

Mechanisation reduces manual labour and cycle time, increasing area coverage per unit time and enabling timelier field operations, which improves crop management and labour efficiency.

Always use fitted guards, shields and emergency stops; perform pre-start inspections; wear appropriate PPE; avoid loose clothing; follow lockout/tagout during service; and keep bystanders, especially children, away from operating equipment.

Yes. They are engineered for muddy, uneven and brushy fields through robust frames, reinforced cutting/working edges and heavy-duty driveline components. Exercise caution on steep slopes and extreme terrain.

Reliability stems from durable materials, proven mechanical components, simplified systems (minimised unnecessary electronics), and service-friendly layouts with easy access to filters, oil points and wear items.

Adhere to regular maintenance, use quality fuels and lubricants, keep machines clean and dry, store under cover when not in use, replace wear parts promptly, and follow manufacturer service intervals to prevent corrosion and cumulative wear.